| Pneumatic | Supply Air Pressure | 0.14~0.7 MPa |

| Valve Leakage | <0.6L / H | |

| Air Consumption | <36L / H | |

| Air Supply | According to ISO8573-1 Size and density of particulates: Class 4 Oil concentration: Class 4 Dewpoit:Class 4 or 10K below operating temperature | |

| Input/Output | Actuator | Single acting, Double acting |

| Travel Range | Linear: 10~100mm(10-20mm,1:6 transmission ratio is optional); Rotation angle:30~105º | |

| Input Current | 4~20mADC,Minimum input current:>3.8mA,split range start and end point adjustable | |

| Feedback Output | 4~20mA DC | |

| Digital Input | 1 dry contract | |

| Digital Output | Electronic switch:2 channel | |

| PiezoValves Switch Time | Average failure free time: >2billion | |

| Output Characteristic | Linear, 1:30, 30:1, user defined (20points) | |

| Communication | HART | |

| Display | LCD | 2×7 digitals, dimension:22×38mm |

| Pressure Gauge | Optional, displaying the in and out pressure | |

| Operate | Self Tuning | Automatic calibrate the Zero and Span, dead band |

| Self Diagnose | Show the value of input current , travel time, dead band, etc. | |

| Manual | 3 keys on the front panel | |

| Precision | Dead Zone | 0.1~10%adjustable |

| Linearity | ≤±0.5% FS | |

| Hysteresis | ≤0.5% FS | |

| Environment | Ambient Temperature Range | General type:-(40~80)°C |

| Intrinsic safety: -40~+50°C(T6) /65°C(T5) /80°C(T4) | ||

| Relative Humidity | 5~95%RH | |

| Vibration Resistance | 15~150Hz@2g | |

| IP ProtectionLevel | IP65(According to customer needs) | |

| Explosion-Proof Type | Exia IIC T4~T6 Ga, ExiaD 20 T80/T95/T130 | |

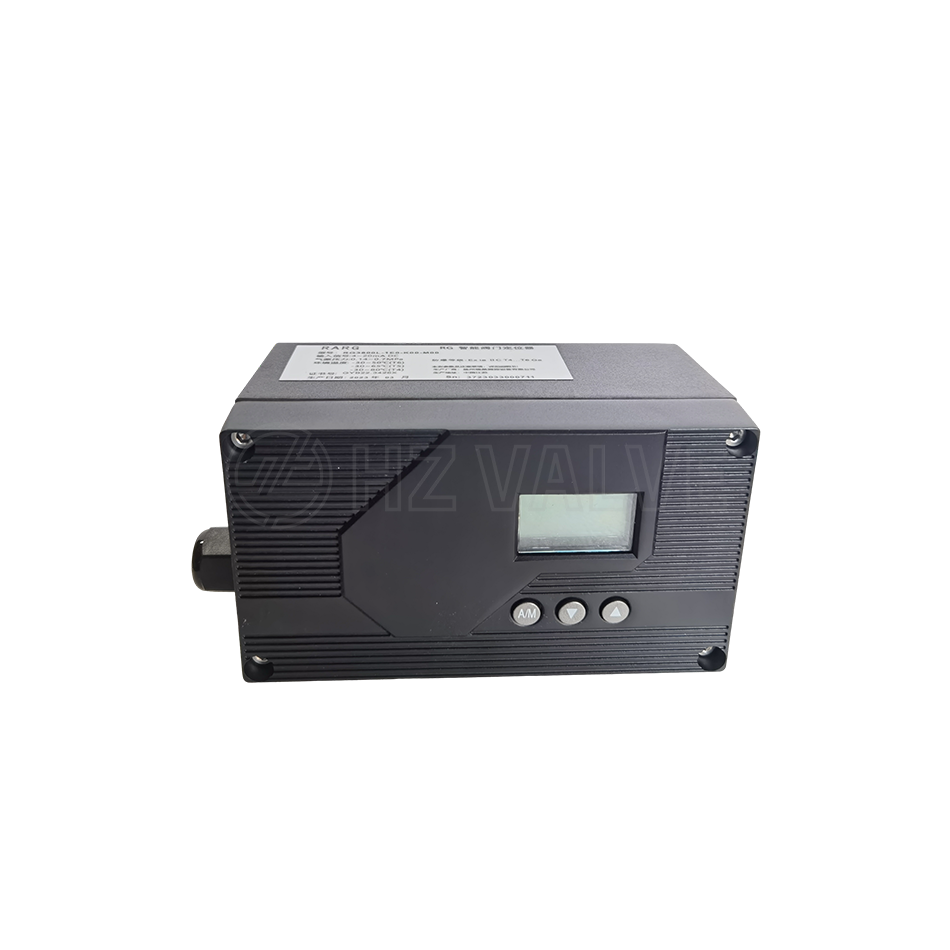

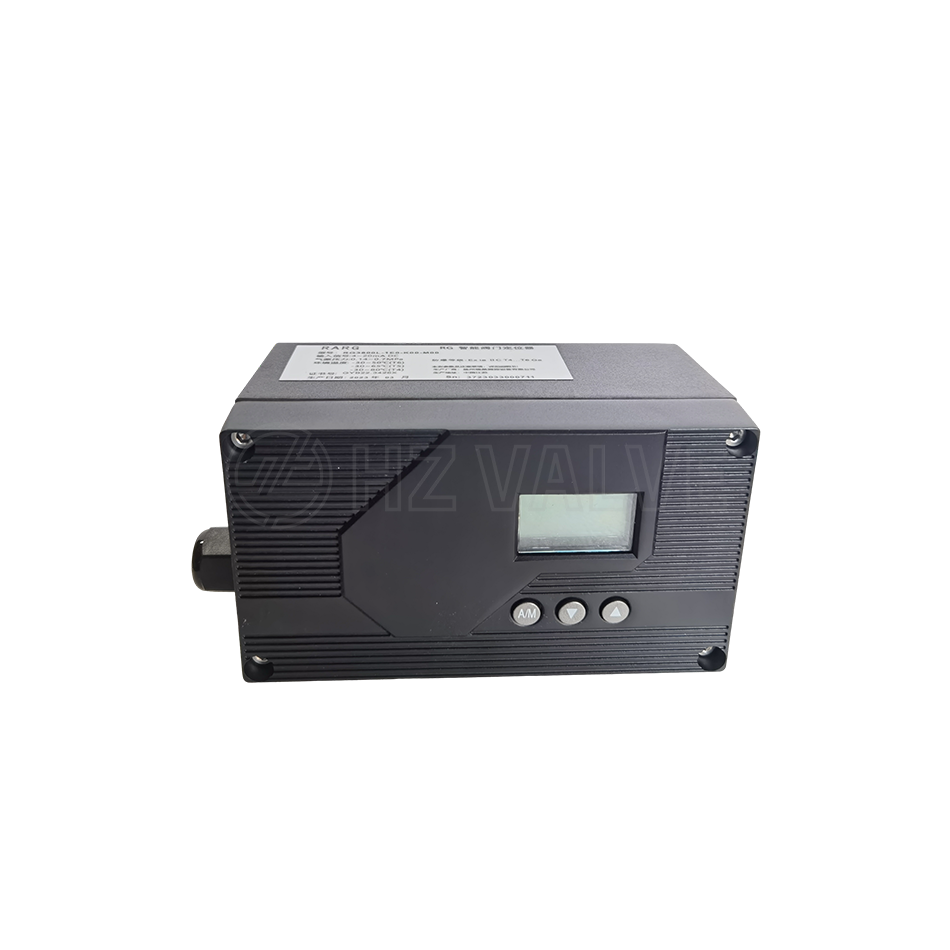

| Appearance | Weight | 2 .0 kg |

| Dimension | 170×96×92mm | |

| HousingMaterial | AluminiumDiecasting |

RG intelligent valve positioner is a two-wire system instrument made by RG. The positioner is a control accessory of pneumatic valve. It is widely used in automatic control systems of petroleum, chemical, electricity, metallurgy, paper and pulp industry and other fields.

RG intelligent valve positioner accepts the 4~20mA valve setting analog signal from the control system. This valve setting value will be converted by an analog to digital converter (ADC) to digital signal then input to CPU. At the same time,instrument gets the actual valve position from location sensors. The two signals are compared by the instrument software so as to control the intake and exhaust of the pneumatic actuator, and drive the valve to reach set point (refer to Figure2-1).

RG intelligent valve positioned is based on micro process or technology. It can overcome friction and the imbalance power on the control valve well, and improve the response speed of control valve, which makes the position set rapidly and accurately. It is not only able to completely substitute conventional valve positioner, but also is able to directly access HART network, exchanging information between control system and positioner.

HUIZHENG AUTOMATIC CONTROL VALVE GROUP CO.,LTD

HUIZHENG AUTOMATIC CONTROL VALVE GROUP CO.,LTD