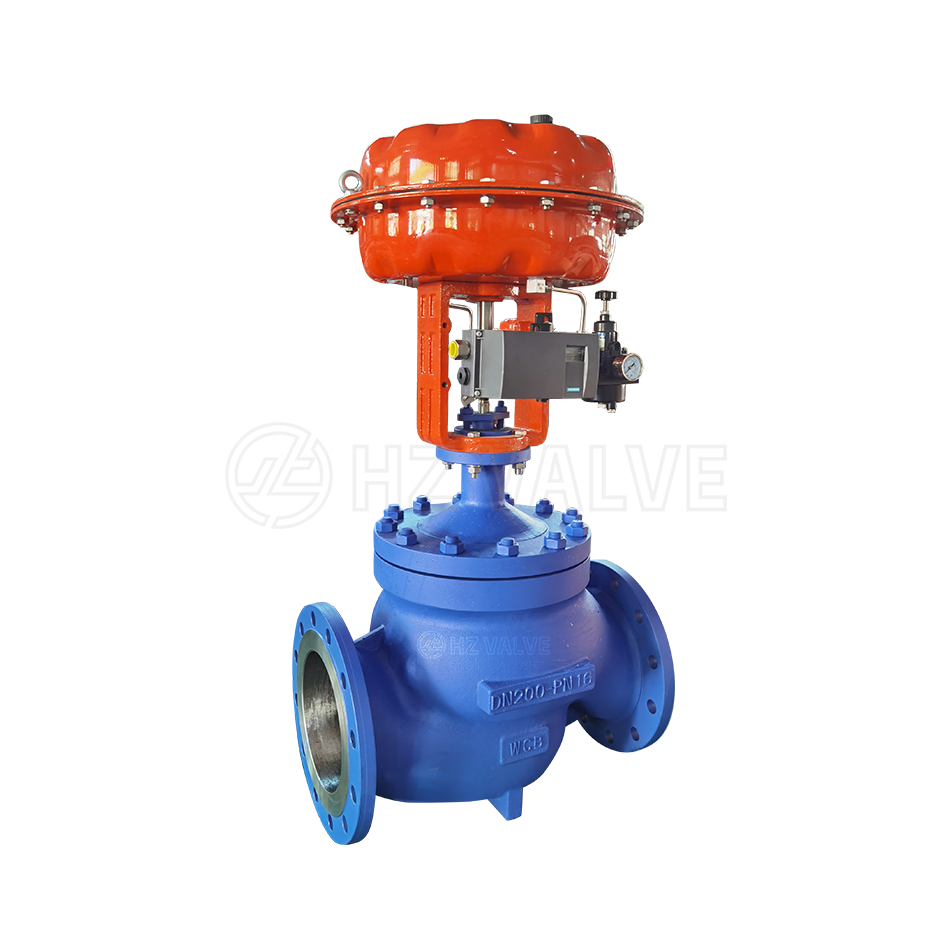

Type:ZJHM cage guide control valve features:

Size:DN20~DN600 1/2”-24”

Pressure:PN1.6MPa~ PN42 MPa 150LB-2500LB JIS 10K ~JIS 40K

End connection:RF RJ ,BW

Material:WCB,WC6,LCB,CF8,CF8M,CF3M,904L, 316Ti ,A105 ,F304,F316, Duplex stainless steel, Monel, Hastelloy, (Special Materials on Request)

Bonnet type: Normal type(P):-45~+250℃

Extend type with I type-High temperature type(EI):+250~+566℃

Extend type with EII type--cryogenic type(EII):-45~-196℃

ZJHM cage guide control valve Trim type:

Pressure-balanced spool

Flow characteristics: Equal Percentage ,Linear type

Leakage class:class IV(stand type ) class V, class VI

Adjustable ratio:50:1

Actuator type :

Pneumatic actuator:Pneumatic diaphragm actuator or pneumatic piston actuator

Air supply: 3-7bar

Failure position :Normally closed ,Normally open

Cage guide Control Valve

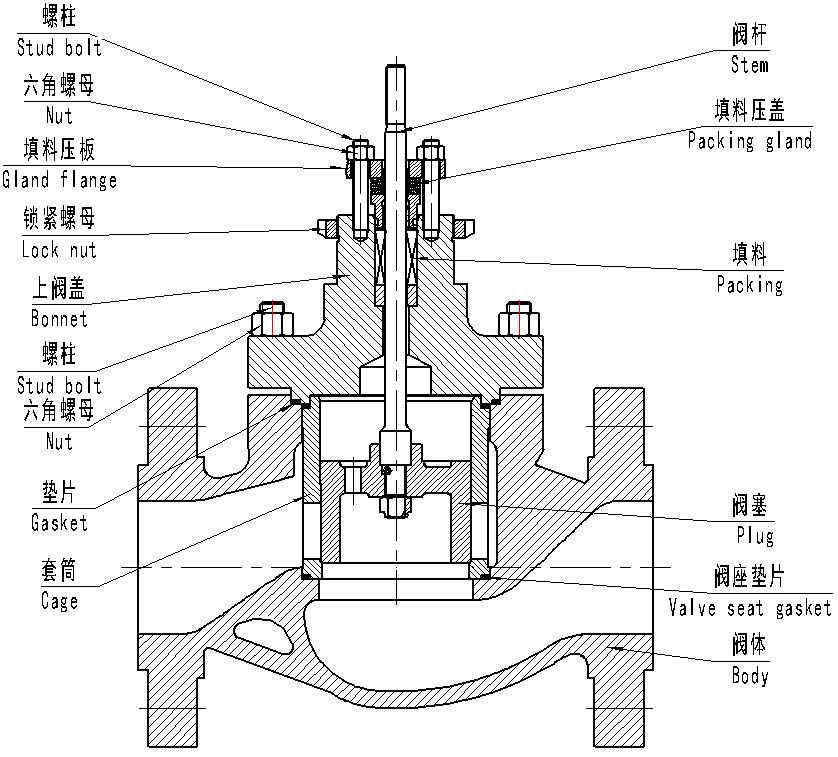

Pneumatic cage guide control valve adopts cage guide structure. This type of valve has a compact structure and an S-shaped fluid channel. It is also equipped with a guide wing to improve the balanced flow of fluid around the sleeve, resulting in small pressure drop loss, large flow rate, wide adjustable range, and high accuracy of flow characteristics, in line with IEC60534 -2-1-2011 standards. The regulating valve has good dynamic stability, low noise and little cavitation corrosion. Suitable for occasions requiring thermal insulation. When the crystallization temperature of the process medium is lower than the ambient temperature or the fluid temperature decreases, causing the viscosity to increase or the fluid to solidify, a steam insulation jacket device is added to the valve body and upper valve cover to enable the process medium to meet the needs of process control. . The leakage of the regulating valve complies with ANSI FCI 70-2-2013 standard.

HUIZHENG AUTOMATIC CONTROL VALVE GROUP CO.,LTD

HUIZHENG AUTOMATIC CONTROL VALVE GROUP CO.,LTD